Ace Info About How To Build Anaerobic Digester

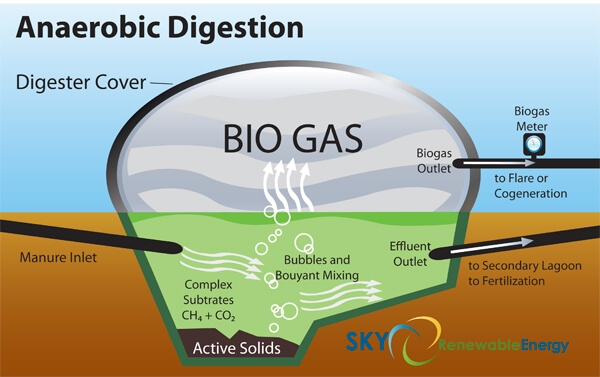

The leftover biomass can also be used as fertilizer, which is why anaerobic digestion is so popular on farms.

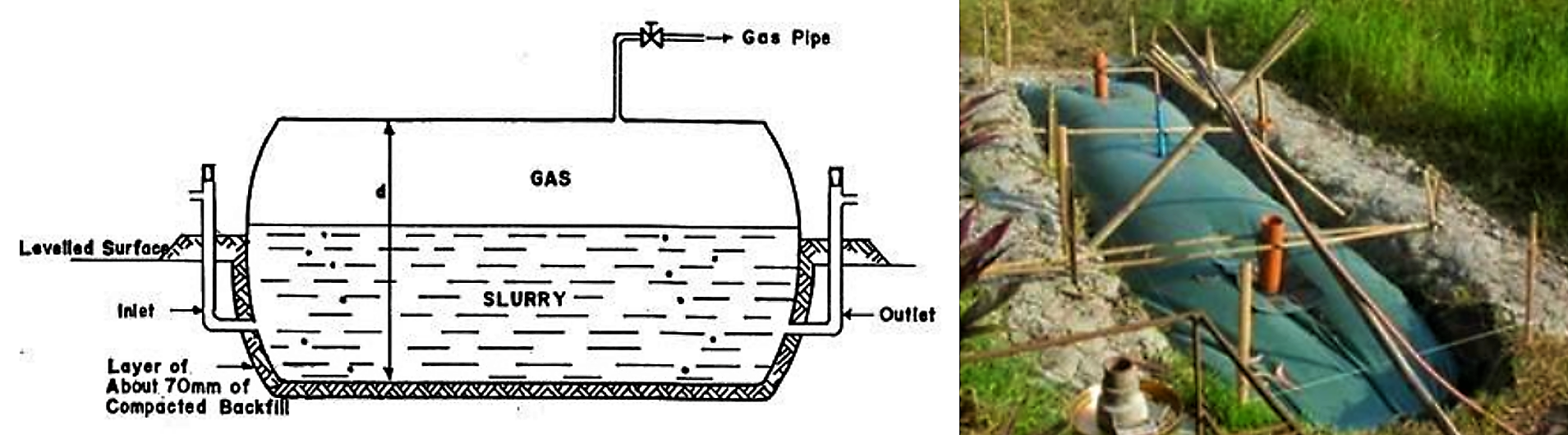

How to build anaerobic digester. The design should attempt to maximize the amount of biogas produced per unit time,. A flexible hose connected the pipe from the upturned barrel to a pipe from the top of the oil drum. There will be a folder.

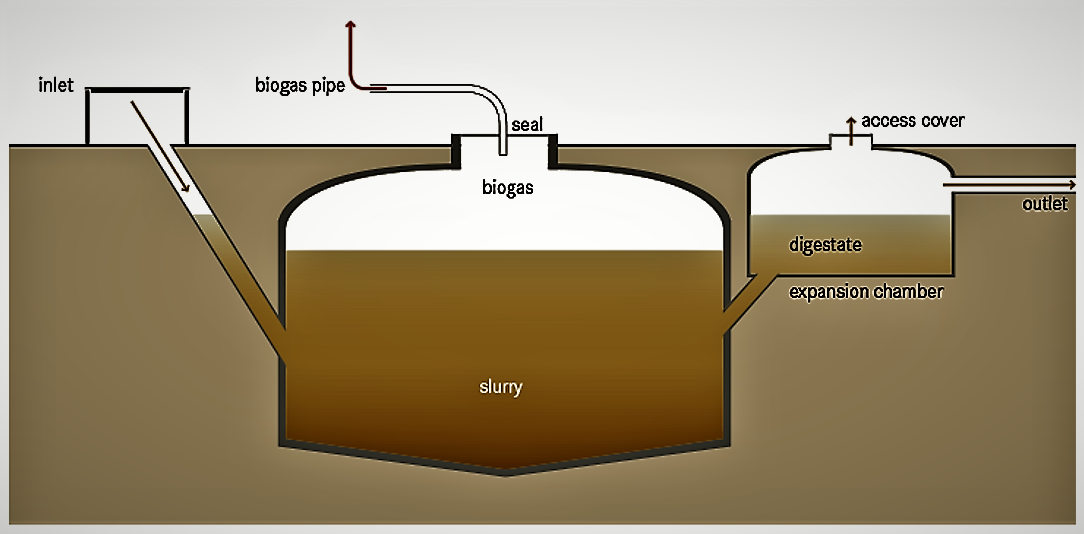

Ultimately, however, the technology behind anaerobic biogas digesters is pretty darned simple. We will need biomass to make an anaerobic digester. Will it work on your farm?

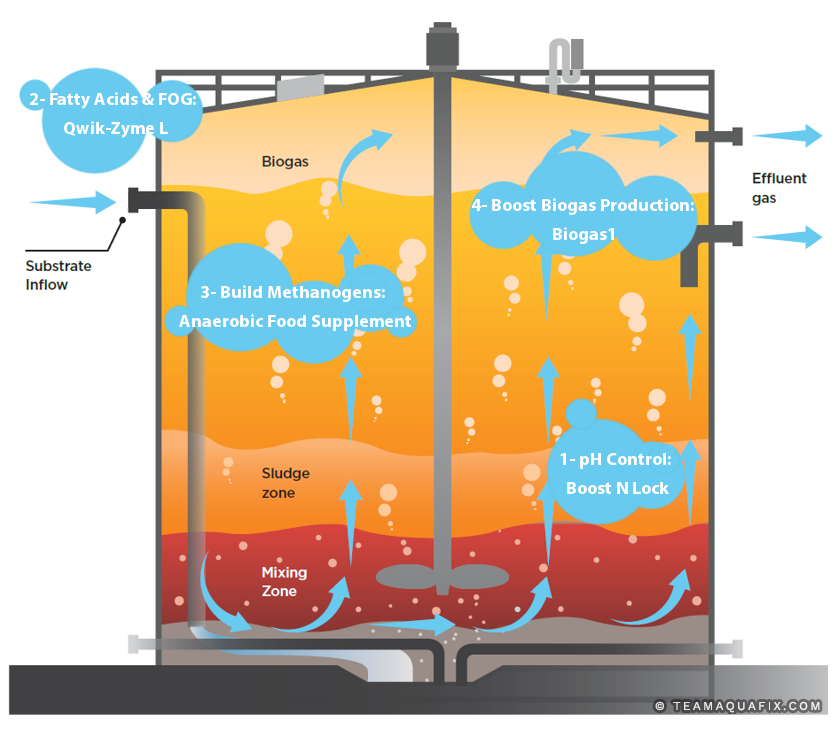

The purpose of this project was to design and build an anaerobic digester to meet the following criteria. In some digester designs the stage 1 process is carried out in a separate reactor. All three are plastic (hdpe), and all.

With a combined total of 120 years in service, 30 billion cubic feet of. I bought three different containers for this project: Wrap digester with heat tape.

Approximately $400,000 to $5,000,000 depending upon the size of the operation and. Attach the heat tape with aluminum tape. Specialty blends of micronutrients, microbial cultures, microbial growth enhancers and neutralizing agents when.

For example, cow manure, grass clipping with soil or any other waste, cow manure serves a starter to produce biogas. A dozen digesters in two decades. Regenis has built more manure digesters than anyone in the western united states.